Imagers capable of interpreting electromagnetic radiation reveal an immense amount of condition data that business owners often need to guarantee the safe and reliable installation of electrical systems and mechanical assets.

There are several types of imaging cameras available, such as thermal and multispectral, each with its own speciality and role within the commercial and industrial economy. So, knowing which is best for your business's needs can be difficult. Read on to explore what thermal and multispectral cameras are used for and discover the best choice for your electrical and mechanical assets.

What Is Thermal Imaging?

Thermal imaging focuses on recording the thermal radiation emitted from an observed object. These practical tools consist of phone modules, handheld cameras, and static observation units, but they all have the same role of reading infrared radiation and creating a visual interpretation of it.

The user will simply record what they are surveying in a non-invasive manner, like any other video camera, resulting in detailed thermal information that will inform other maintenance and safety elements of your business.

Active and Passive Thermography

There are two categories of thermography: active and passive. Active requires the observed object to be artificially heated so the cooling is observed and analysed by the imager. For example, if the cooling is not uniform, it will reveal flaws in the material being observed. Passive is a more common choice and the only one used in electrical or mechanical installations due to its non-invasive simple observation function.

Thermal Imaging Applications

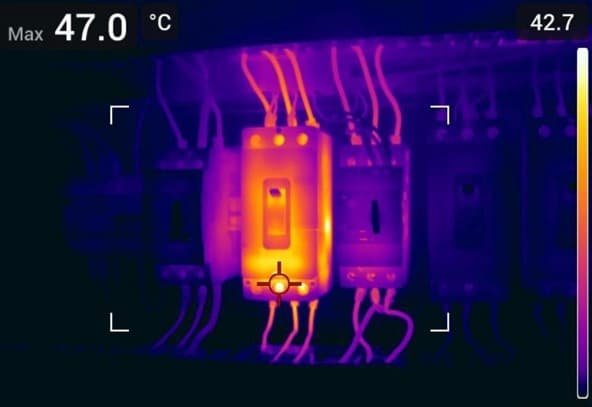

Thermal imaging is used in every sector and industry for various roles, but the most prominent are maintenance and diagnosis. The efficient operation of a thermal imaging camera enables trained staff to assess the condition of any assets or even whole buildings to identify potential problems that threaten your activity. Electrical infrastructure and mechanical assets both have easy-to-find signs of wear or damage when observed for their thermal condition. For example, machines without appropriate lubrication will cause friction heat on parts, whereas inoperative electrics will reveal an absence of heat.

What Is Multispectral Imaging?

Multispectral cameras have a broader focus than the previously discussed thermal imaging cameras, as their purpose is to capture and process simultaneously multiple electromagnetic wavelengths identified as spectral bands. These cameras are generally installed in static locations to conduct automated observations and act as part of an emergency alert system.

What Are Spectral Bands within MSI?

Spectral bands are named sections along the electromagnetic spectrum; cameras like the FH series will capture more than a thermal camera but less than a hyperspectral imaging device. Generally, a multispectral imager will measure roughly three to fifteen various bands, each related to a specific focus.

For example, in the context of electrical and mechanical installations, True-colour is used. True-colour uses only RBG (red, green and blue) to create an observation palette similar to thermal palettes where each colour gradient has data associated with it. These cameras observe a range of additional bands that include near, mid, and far infrared, as well as their most popular functions within this sector, observing ultraviolet and thermal radiation.

Applications for MSI Cameras

The ultraviolet observations are related to the near-infrared (NIR) band and, in the context of this blog, specifically refer to machine vision and security applications. Machine vision uses external observation systems like multispectral cameras to provide detailed condition information for the automated system to interpret and act upon based on its programming. Quality control systems rely on these cameras to collect a broad range of product condition data instantly; any products exceeding established parameters will be flagged for inspection.

For site security applications, these adaptable cameras are powerful tools as they will observe the designated area regardless of the darkness of night or any obscuring weather. The cameras’ thermal observation abilities mean they will register any people or vehicles in sight and are usually connected to smart software systems that will differentiate between authorised and unauthorised personnel.

What Do Electrical Installation Surveys Need?

Electrical surveys are an essential part of a preventative maintenance program, but they are also used for emergency diagnosis if unexpected faults occur. For an effective survey, you need to be able to quickly assess the condition of your electrical systems, ideally without interrupting those systems and creating downtime for your workplace. Additionally, for diagnosing faults, you need a mobile option that is capable of following the extent of your infrastructure to track down any wear or damage along various connection points.

Which Is the Best Choice?

Handheld thermal imaging cameras are the best choice for electrical system installations, maintenance and diagnosing problems. Our range of industry-grade cameras are powerful, lightweight tools that will fulfil all those requirements and guarantee you get the thermal condition information you need about your electrical system.

What Do Mechanical Installation Surveys Need?

Mechanical asset surveys are also a vital part of a predictive or preventative maintenance program. Businesses that rely on mechanical assets such as large manufacturing equipment and conveyors or smaller mobile vehicles will need to know of any wear as early as possible to ensure their longevity and reduce downtime.

These surveys will vary depending on the environment; for example, a commercial or industrial workfloor is more contained than an infrastructure facility, but both will have a range of essential mechanical assets. These machines will need to be monitored either on a regular schedule or persistently. If they are installed outside, they will also need monitoring for interference as well as wear and tear.

Which Is the Best Choice?

The best choice will depend on your business's scale and the assets involved, but generally, multispectral cameras are the best choice for monitoring mechanical assets. Aside from all the features discussed, these cameras are also capable of monitoring the thermal characteristics of large machinery and providing the information your maintenance teams will need for asset care. For example, machine faults will grind and lead to heat friction as the metal wears down. If ignored, the parts will eventually fail and create far more downtime for your business than is needed.

Their multi-function roles make them excellent for these persistent monitoring tasks; however, if your machine assets are all securely stored indoors and only require regular condition checks, then we’d recommend a handheld thermal imaging camera as an efficient alternative for your maintenance programs.

Thermal and Multispectral Cameras Available at Thermascan

At Thermascan, we maintain a large stock of the highest-quality imaging cameras on the market. We guarantee we have an effective camera for you, even if only for hire, to meet your business’s specific needs and provide your teams with the data you need for your monitoring and maintenance programs.

Contact us to discover which of our products will best suit your workplace needs.